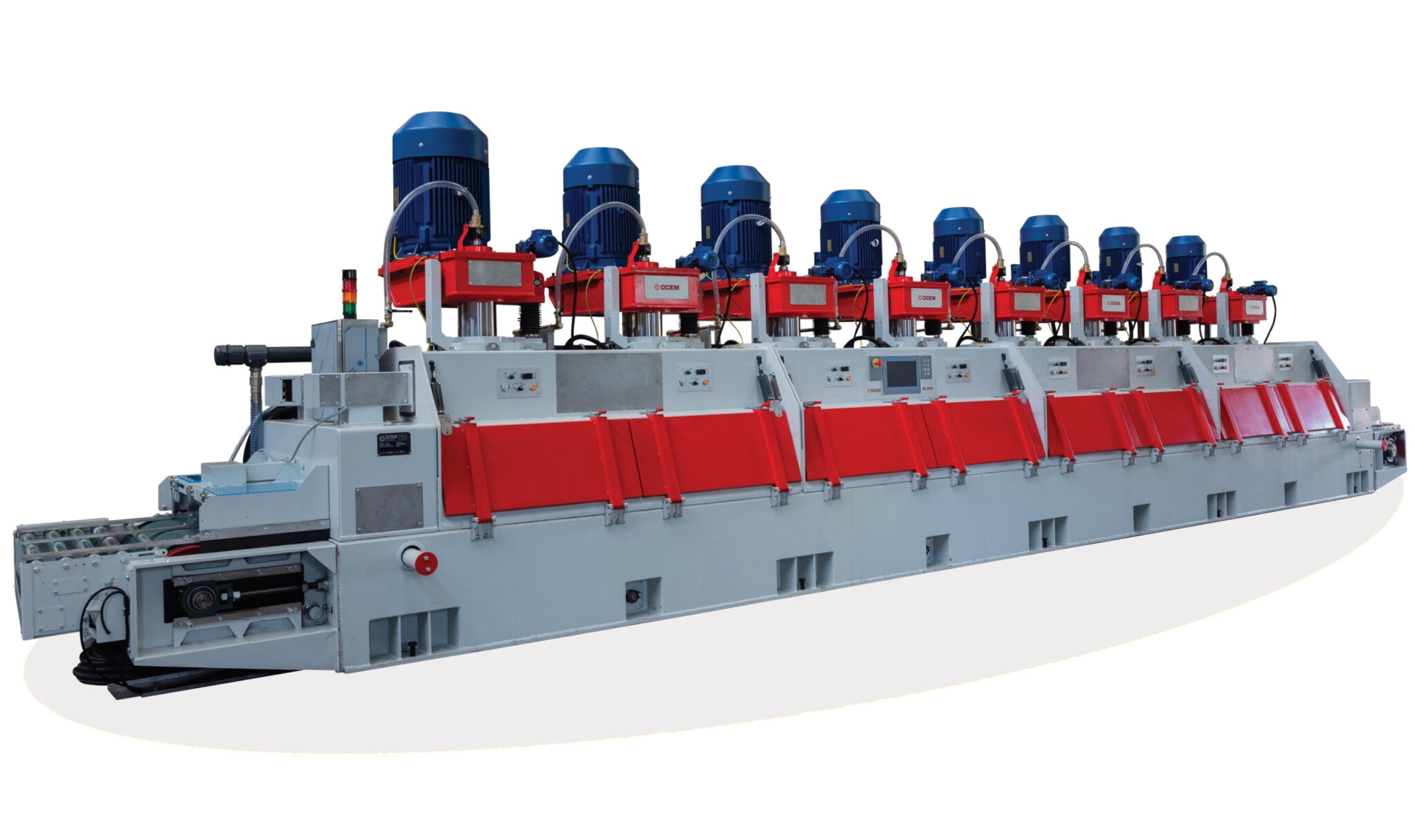

Calibrating Grinding and Polishing Machine for TILES and SLABS

OL/OLC 400-700-800-1000

Technical Info

- Strong electro welded steel structure composed of lower and upper frames on which the calibrating / grinding heads are installed

- Modular structure for machines up to 12 heads

- Multilayer PVC belt to transport the tiles

- Belt sliding runway made in HARDOX wear resistant steel

- Strong stainless steel internal tiles guides are easy to adjust to different tiles sizes

- Motorized roller conveyor at entry and idle roller conveyor at exit

- Calibrating / grinding heads mechanically adjusted

- Working speed of the belt easily adjustable directly from the operator panel between 0,5 and 6 m/min

- Closed loop control of the belt speed

- Amperometric control of the calibrating process

- Amperometric tracking system for the grinding process

- Elecromechanical jacks with orthogonal axis and ball screws for the up/down movement of the heads

- Standard thickness of the tiles up to 130 mm

- Standard stroke of the heads: 200 mm

- Control of the tiles thickness at the entry of the machine with out of tolerance alarm

- Independently adjustable upper and lower air dryer to dry the tiles at the exit of the machine

- Installed power on each head up to 50 K

- Diameter of the working heads 560-850-960-1160 mm for a workable surface of 440-700-850-1050 mm (capable to calibrate / grind up to two rows of tiles 500×500 mm or a slab of 1050 mm)

- Standard useful width 400 / 700 / 800 / 1000 mm to calibrate / grind more than one row of tiles

- Heads suitable to be equipped with carborundum grinding wheels or with fast change abrasive segments

- Enclosure and inspection doors made according to CE safety standards; ergonomic design to avoid water leakages while opening (patent pending)

- Epoxy paint resistant to external agents, following controlled cycles of: phosphating wash, degreasing wash, application base coating (>50 micron) and high thickness finishing ( >400 micron)

- Simple machine foundations

- Cooling water perfectly distributed on all calibrating / grinding surfaces via centrifugal distribution system

- Control system with SIEMENS S7 PLC control system

- TE.SE.O. system for remote assistance (optional)

- Dedicated control panels on each head and a general touch screen operator panel for complete control of the machine working data

- Water consumption from 2 to 4 m³/hour per head

- Automatic filling/emptying of the machine at beginning/end of the shift controlled by software

- Opportunity to choose between calibrating or grinding heads directly from the operator panel

- Interchangeability of the software interface between mechanical and pneumatic heads